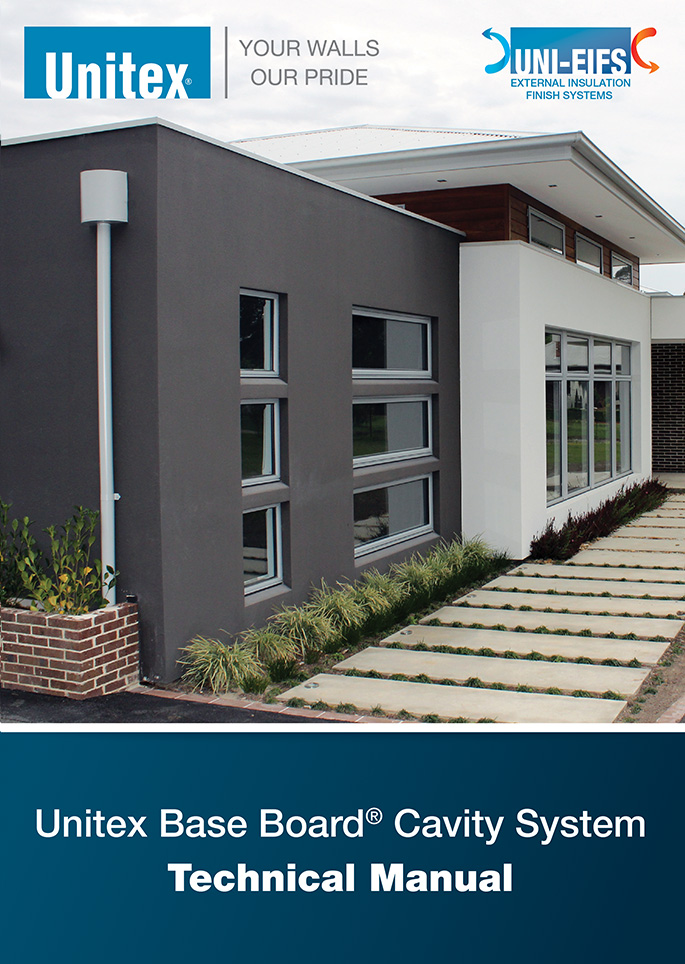

Unitex Baseboard Lightweight Cladding System

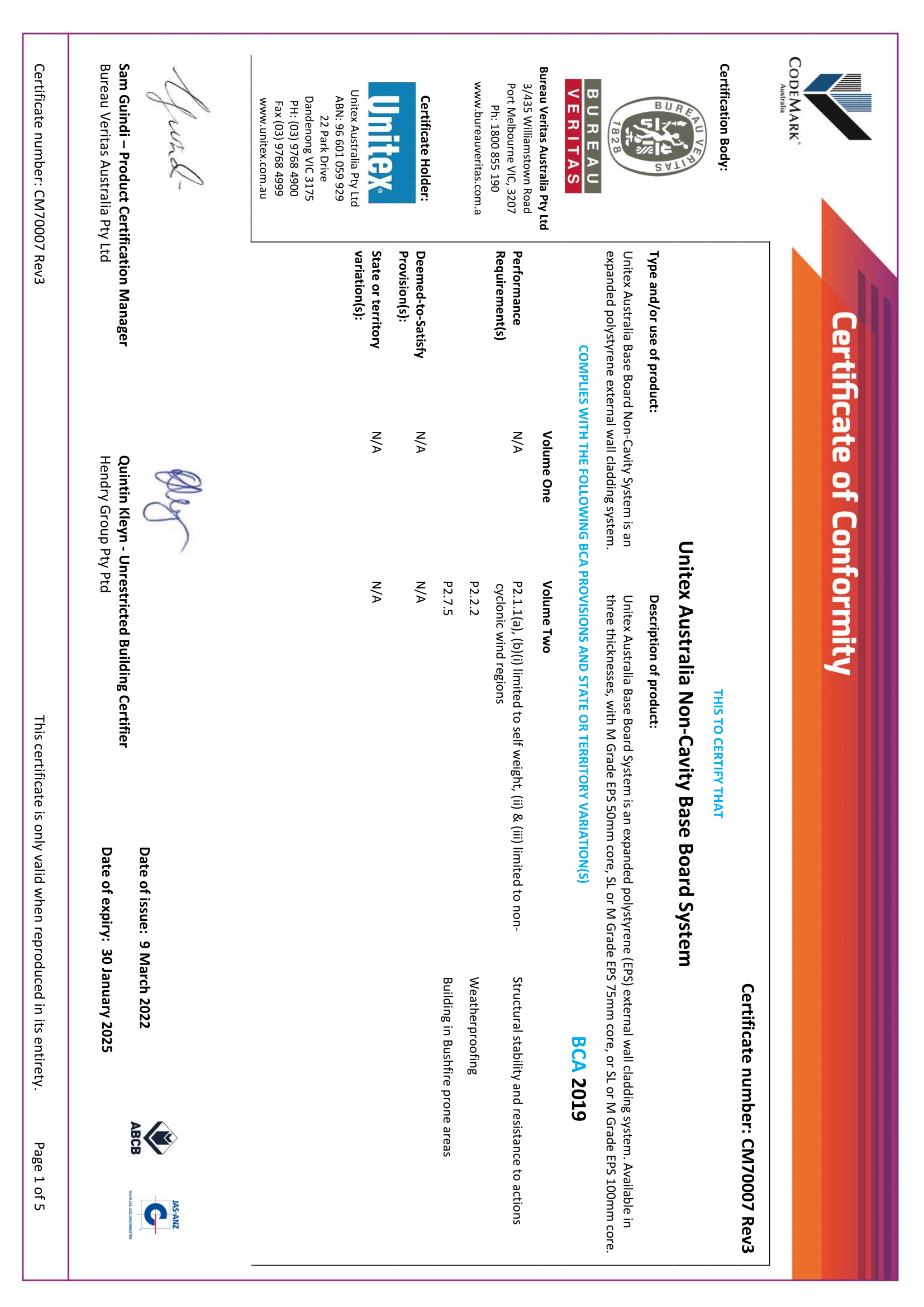

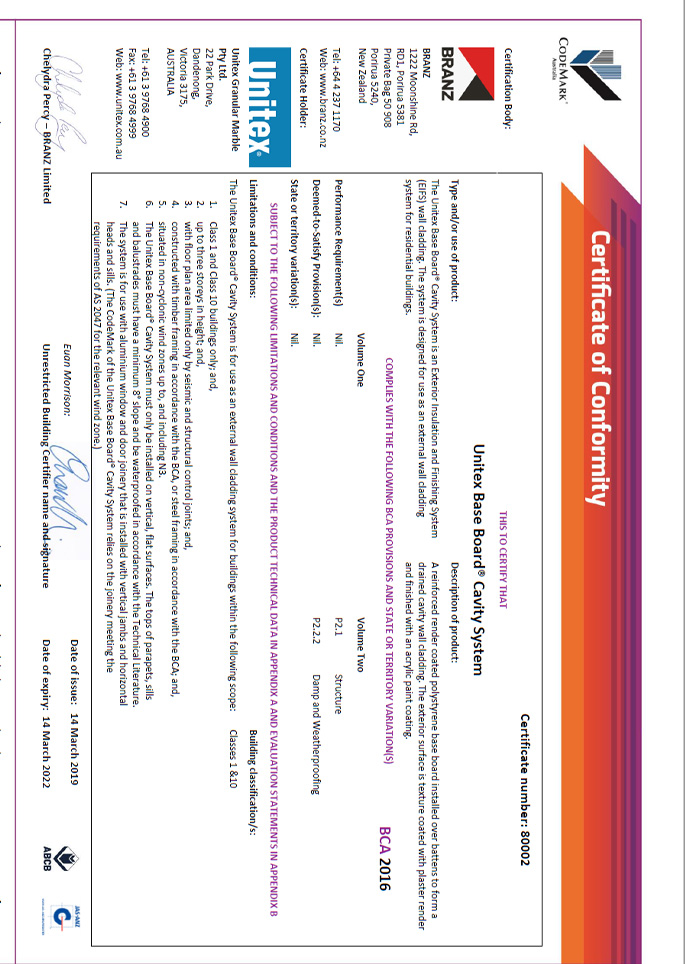

The Unitex Uni-Base Board is made locally at the Unitex manufacturing facility in Dandenong (Victoria, Australia). Unitex Uni-Base Board System is fully compliant to the NCC (BCA) for use on Class 1 and 10 buildings (for Class 2-9 buildings please contact Unitex for options). All Unitex manufacturing processes undergo regular internal audits, along with an annual external audit by CodeMark and BRANZ Assessors so that Unitex can confidently claim that all made product components and accessory components are fit for purpose and quality approved.

The accredited system incorporates the Unitex nominated components as tested and allows nil substitution. The Unitex Uni-Base Board System is available in a standard size sheet of 1200mm x 2400mm at the required thickness for the thermal comfort specified for the project (generally 50mm, 75mm, or 100mm, plus a coating thickness of 6 -15mm over surface and importantly, over fixings).

The only approved and accredited method of installing the Unitex Uni-Base Board System on site is by using, and applying, the specified components as is detailed in the Manual, and further detailed in the Unitex Technical Manual available here

Baseboard System Variations

Uni-Base Board Cavity System

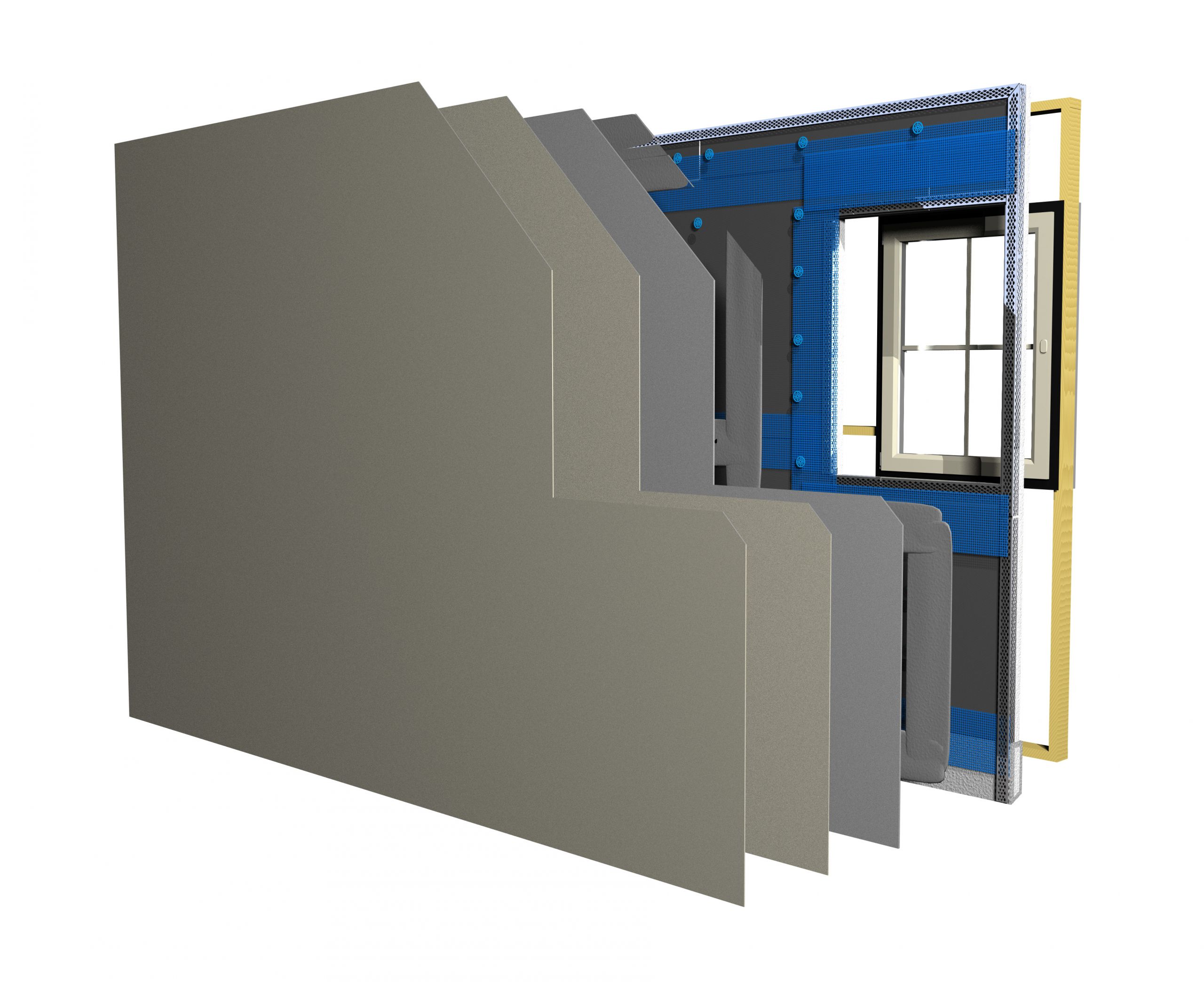

The Unitex Uni-Base Board Cavity System provides Architects, Designers, Builders, Developers, and Home Owners with Australia’s ultimate weatherproofing security that builders have always enjoyed with standard brick veneer construction cavity walls but with added ultimate insulation values and energy saving benefits. The benefits in choosing the Unitex Uni-Base Board Cavity System, other than the proven conformance to the National Construction Code, is in situations where there is moisture or water ingress due to poor design or detailing of features such as junctions and parapets, non-appropriate window, door fittings, other penetrations and or lack of or not fit for purpose expansion joints. It is then, through the Unitex Uni-Base Board Cavity System that this water ingress or leak is channelled away from the internals down the cavity between the Uni-Base Board System and the sarking covered building frame to eventually leave via the base installed Unitex Cavity Closer. This system therefor offers fail safe protection.

The Unitex Uni-Base Board Cavity System is for use in all situations except where BAL-29 and above (BAL-40) are required. Any Base Board thickness below 50mm does not conform with Codemark.

The Uni-Base Board Cavity System, when installed to the Unitex specifications, is the ultimate and Australia’s leading accredited system available, offering fail safe leak security to the internal and framing substrate.

For your copy of the Building Surveyors Checklist Flipbook, please contact your Unitex Technical Sales Representative or Unitex Marketing. Or view online here.

Uni-Base Board non-cavity System

The Unitex Uni-Base Board Non-cavity System is the most currently used system for those Builders not choosing full Codemark accreditation.

The Unitex Uni-Base Board Non-cavity System or ‘Direct Fix’ Uni-Base Board System is a system that is direct screw fixed to the sarking clad building frame which provides ultimate insulation to external walling (up to R-Value 2.6 for full wall with 75mm BB, but much higher for 100mm upwards). The Unitex Uni-Base Board Non-cavity System is BRANZ and BRAC (Building Commission) accredited as an installed system (not as individual products) to ensure ultimate protection and comfort for you and/or your clients.

For confirmation that your Unitex Uni-Base Board Non-cavity System is installed correctly ensure your Unitex Technical Sales Representative is involved from the beginning and you are provided with a signed Unitex warranty for proof of accreditation and conformance. The Unitex Uni-Base Board Non-cavity System must be installed as per the Unitex full installation manual. Please further note that Unitex advises that care must be taken to correctly install regular expansion and contraction joints, and have suitable window and door fittings designed for self-drainage. The stipulated (in system) Unitex Render and Applied Finish appearance is desired for pleasing durable textures, and ochre like colours. Any Base Board thickness below 50mm does not conform with Codemark.

For your copy of the Building Surveyors Checklist Flipbook, please contact your Unitex Technical Sales Representative or Unitex Marketing. Or view online here.

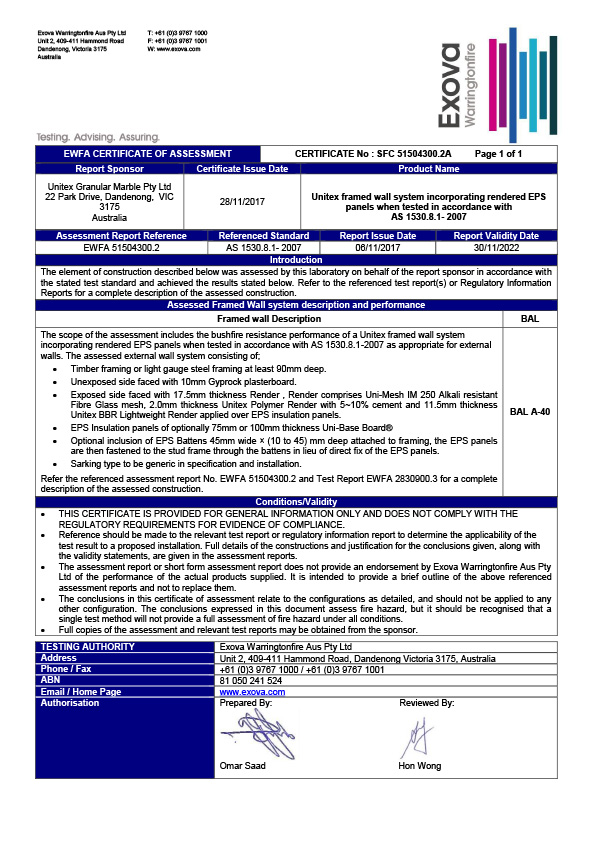

Uni-Base Board System (BAL 40)

For your trust and peace of mind and to comply with the requirements of Bushfire Attack Level 40 (BAL-40) it is strongly advised that a Unitex Technical Sales Representative quote on all the components required to complete the project to achieve complete conformance. In order to achieve complete conformance to BAL-40, your Unitex Technical Sales Representative will sign off critical installation stages – prior, during and on completion – for the Unitex warranty sign off for BAL-40 accreditation.

We take pride in the quality of our systems, and the accreditations they have achieved. It is with this in mind, and for your protection and protection of your clients, Unitex only allow approved and accredited Unitex Installers to install any Unitex Uni-Base Board System BAL-40 projects. For your safety and protection, this is a strict policy of Unitex. Any Base Board thickness below 50mm does not conform with Codemark. For those interested in becoming an approved Unitex Installer, please refer to our Accredited Contractors information.

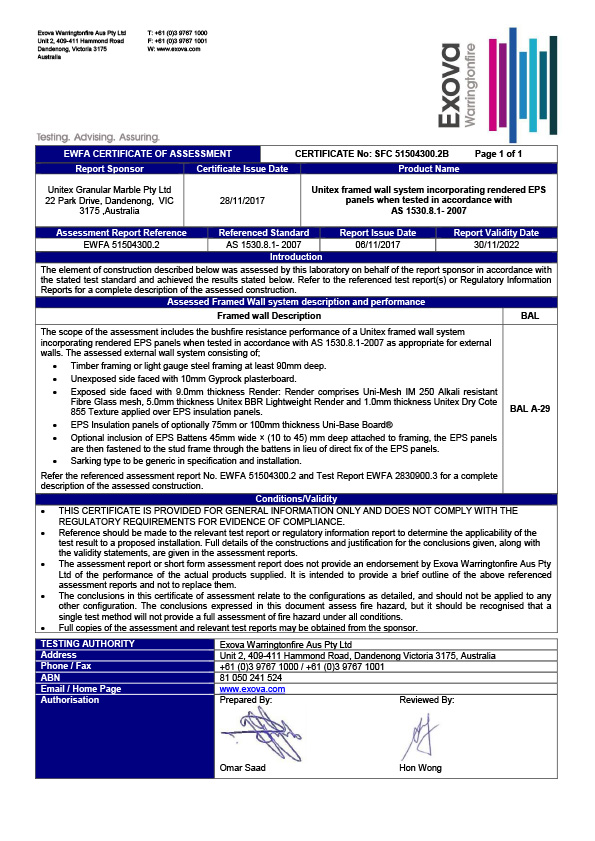

Uni-Base Board System (BAL 29)

The Unitex Uni-Base Board System (BAL 29) is accredited to pass Bushfire Attack Level 29. A Non-cavity Uni-Base Board system that must adhere to the strict installation and coating specifications. Unitex strongly advises our on-site involvement prior, during, and at completion of installation (as per the Unitex installation manual) as Unitex must sign off as conforming and complying with all requirements of the BAL 29 Unitex walling System.

With Unitex sign off and involvement your building surveyor will have proof from Unitex, as the system provider, for confirmation of full compliance to the accredited system. Any Base Board thickness below 50mm does not conform with Codemark.

At Unitex we always say – Your Walls. Our Pride – so get Unitex involved early to prevent shortcuts and peace of mind for all stakeholders. Contact Us.

Uni-IB Board

The Unitex Uni-IB Board System, to equate to the Unitex Uni-Base Board System once installed, is to be first pre-coated with Unitex Polymer Render (with added 5% cement) which is applied with a Notch Trowel to a minimum depth of 3mm, and embedded Unitex Uni-Mesh IM. This is to achieve the Unitex Uni-Base Board which is then followed with all the system requirements to achieve the Unitex Uni-Base Board System (using the relevant Uni-Unitex Base Board System manual) for warranty (refer to Technical Manual for installation).

For your copy of the Building Surveyors Checklist Flipbook, please contact your Unitex Technical Sales Representative or Unitex Marketing. Or view online here.

| Sheet Size | Sheet Thickness |

|---|---|

| 2400mm x 1200mm | 50mm |

| 2400mm x 1200mm | 75mm |

| 2400mm x 1200mm | 100mm |

| 2400mm x 1200mm | Thicker sheets available upon request |

Baseboard System Components

Baseboard System FAQs

The first External Insulation Finishing System (EIFS) project by Unitex was built in 1984. These were for Victorian Housing Commission blocks of 4-6 units and single concrete houses in Jordanville (Chadstone) and Preston. The then Unitex EIFS system proved successful in solving internal wall condensation issues (that had up until that time been unsolvable) and internal living comfort. Unitex were the first in its field to have successfully manufactured the EIFS system, in Australia, and were also the first Australian EIFS projects to be monitored scientifically by The Melbourne University Building Energy Research Group.

The Unitex Base Board system can be used on external walls of Class 1 to 10 Housing and Commercial Projects. It can be installed by direct fix to the timber or steel frame or via cavity battens. It can also be installed on battens for older walls (brick, block, weatherboard, compressed cement fibreboard sheeting etc).

*Unitex Base Board is part of the Unitex EIFS range

Primarily to have a strong insulating walling system that both protects the building from the weather and decorates with colour, and gives a textured masonry effect of your choice. Around the world similar systems are seen as providing the highest insulating walls whilst measurably reducing on-going energy bills.

With a specified number and array of mechanical fasteners screwed (minimum of 30 mm) into the timber or steel frame. There are fastners to suit all thicknesses of Unitex EIFS and conditions (ie coastal, inland, near breaking surf etc, wind classification areas).

Yes, Unitex recommends that Uni-EIFS systems are only installed by an experienced Trades person. Unitex can arrange for a local recommended Trades person to quote and carry out the installation or Unitex also offers a plan and on site quoting service for the customer’s peace of mind. Unitex installation manuals and Guidelines are also available on our website for your own understanding of the process. Unitex Technical Sales Representatives are also available for technical support and site inspections.

The Unitex EIFS Technical manual and all instructions required is on the Unitex website, or please contact Unitex and our experienced Technical Sales Rep will check the purchase records and if needed will attend an onsite inspection.

The Unitex Base Board System generally costs similar or less than rendered brick veneer etc, however in R-value (insulating value) offered the Uni-EIFS is approximately 400% more energy efficient than equivalent cost for rendered brick veneer.

Most certainly! The Unitex Technical Sales Force will spend time on site with our valued customers to achieve the best from our products for your project.

When your Unitex EIFS system wall is installed in accordance with the technical manual it will not allow water into your building structure. Uni-EIFS have been tested under Australian Standards for Building Materials flammability and like timber are suitable for use up to 3 floors or 8.5 meters above ground slab based on flammability test standard AS 1530 (part 3). Such systems are not suitable where a 1 hour and greater fire rating is required (i.e. on neighbour or party walls).

The coating thickness is to be at least 6mm above the fixing buttons and insulating sheet (IB Board) providing a SB impact strength of >20 joules.

The findings concluded by the CSIRO testing were submitted to the Building Regulations Advisory Committee (BRAC) as part of the evidence that the Unitex Base Board System is a viable building material able to withstand many different weather and man-made abuses.

Accredited EIFS systems are a Worldwide Recognised Building method and as such are insured in all user countries. As Unitex has a history of over 15 years of EIFS Accreditations and is currently Accredited our systems have never in that time faced any negative insurance issues. Non accredited systems may be refused.

Unitex has been manufacturing defect free EIFS products/systems for approximately 27 years defect free. Andrew Concannon, MD of Unitex states ‘because of this, we know Unitex EIFS systems are still ‘good as gold’ after 27 years. I know from my training in Europe 37 years ago that EIFS in Europe and America are now over 48 years in continual use for externally insulating and protecting building structures.’ The Unitex Speciality Render and Surface Applied Coating System when applied as per manual is maintenance free. However, for a decorative look, or for a fresh look (if so desired) it can be touched up (repainted) if required after 7-8 years.

Yes, and Unitex will advise on best method of repair. Good building practice and regular installation of expansion joints around the perimeter will in general negate most minor frame movement issues.

From your local Unitex office and /or Local Stockist. Also on line. » click here

You can contact the Unitex office on 1800 RENDER. You can also send us your plan online (free plan quote service) via our website.

You can do this via the Unitex website, and we can base our quote on your plan or you can contact us direct (1800 RENDER) or via your local Unitex Stockist.

Orders within Victoria are generally filled and delivered within 48 hours. NSW and other states (including local Unitex Stockists) are generally within 5 working days.

There are several reasons:

1) Immediate protection from the elements. Raw polystyrene, if left un-coated will surface degrade and reduce adhesion of base coat renders, causing possible delamination of renders.

2) The first coat of render applied to polystyrene panels is crucial. This render must have superior adhesion and flexibility than standard renders for brickwork for instance. In the Unitex factory, EPS sheets are transformed into Unitex Base Board sheets by applying alkali resistant fibreglass mesh and a strongly adhering and flexible polymer modified cement coating with a consistent film build with a toothed profile. The special toothed profile makes it easy for the applicator to trowel on the base coat levelling render, (Uni-Dry Cote BBR 8.5 kg), at the recommended film build once the Unitex Base Board sheets have been fixed to the frame, ensuring that only the most flexible render on the market with the greatest adhesion has been applied on your project.

3) Raw polystyrene sheets should not be coated whilst wet as this prevents renders from adhering to the surface. This can cause major delays during winter months. Unitex Baseboard is manufactured inside under controlled conditions.

4) System warranty’s for your peace of mind, Unitex Baseboard is a risk free proven surface.

5) Speed. Unitex Baseboard saves time as the first coat of render is already completed.

The R value is a measure of the insulation value of a complete wall from internal plaster to exterior surface. Brick veneer is typically less than 0.8.

For Unitex Base Board 50mm, the R value is: 2.08 (including sisalation)

For Unitex Base Board 75mm, the R value is: 2.62 (including sisalation)

For Unitex Base Board 100mm, the R value is: 3.2 (including sisalation)

Approx. 8kg m2

Yes, the standard Unitex Base Board System achieves BAL29 and a modified Unitex Base Board System achieves BAL40. Please contact your Unitex representative for further details.

A Unitex Base Block is installed around the permitter at slab (base plate/stud/noggins) and at floor roof line to the first floor base plate (stud/noggin) below the base of the sheets, ensuring the system is completely sealed and no polystyrene is left uncoated preventing degradation. Under no circumstance should raw polystyrene be left exposed.

Unitex Base Board 75mm has been tested with various plasterboard situations. The results of these tests are downloadable below.