SYSTEM PROCESS

All Unitex Systems work on these basic steps

1

2

3

4

Preparation

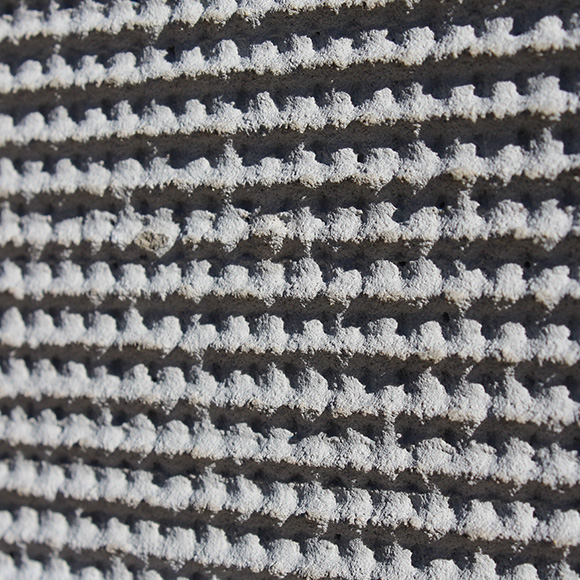

Base Coat

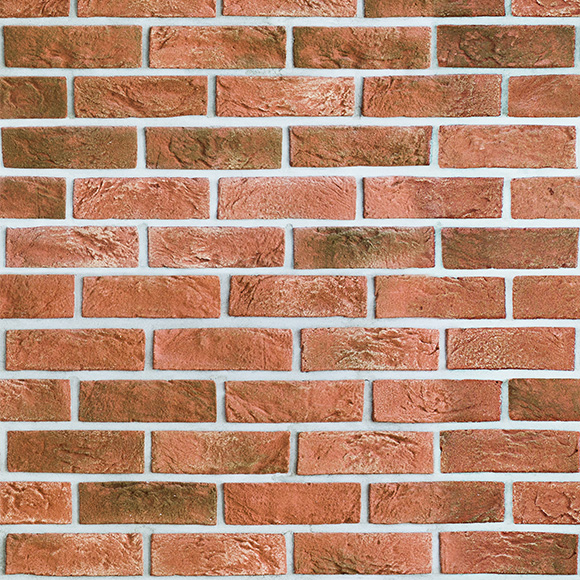

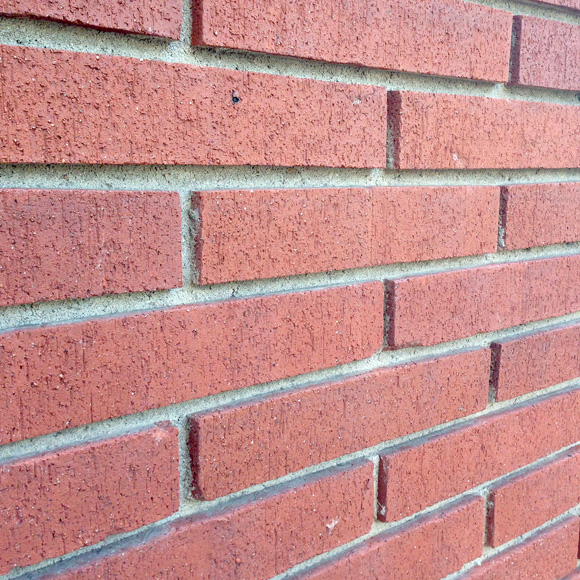

Texture or Finish

Protective Coat

For painted surfaces, a cross hatch test to determine if the existing paint coating is suitably adhered to the substrate is required prior to render coating. If the existing paint coating fails the cross hatch test, all paint must be removed prior to coating.