Description

Download the Unitex Render Brochure here.

Download the Unitex Render Usage & Installation Guide here.

Size: 15L pail

Coverage: 50-70m2 (depending on substrate absorbency) 30-40m2 for AAC substrates

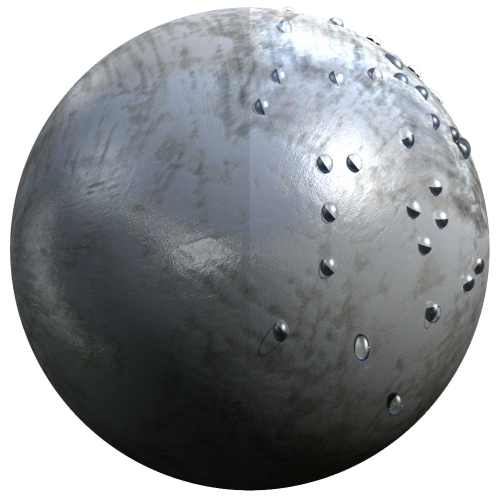

Suitable for: All absorbent masonry surfaces

Apply with: Roller and Spray

Safe Use: Refer to the MSDS

Unitex® Cembond Substrate Sealer is a substrate conditioning treatment and is based on a pure acrylic polymer in a water emulsion specifically formulated for compatibility in the highly alkaline cement environment as a sealer or for cement modification.

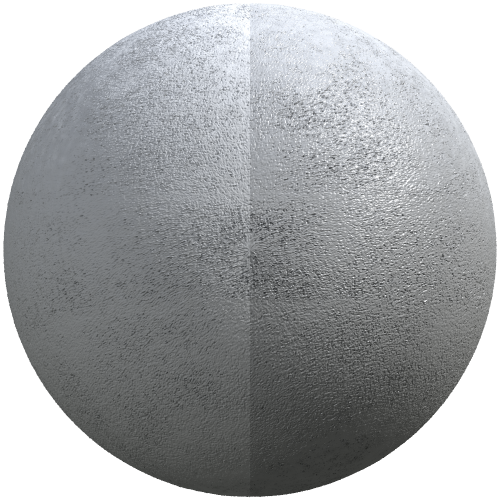

Unitex® Cembond Substrate Sealer is applied to porous masonry surfaces to even out and reduce the porosity (absorption) and create a seal for the later applied coats. This ensures improved adhesion between layers, improved durability of later coats, and evenness of the coating system.

Unitex® Cembond Substrate Sealer is supplied in ready-to-use 15L pails.

Site Requirements:

- Provide complete system in-situ sample for Architect and Builder approval

- Apply only onto clean and dry masonry surfaces

- Mask up all adjoining surfaces, windows, and non-masonry works

- Seal into expansion joints

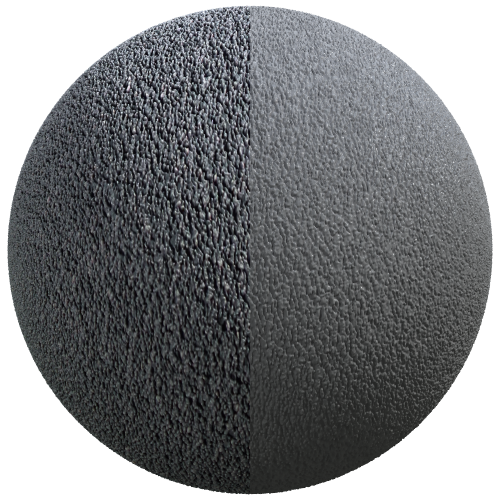

- Over less absorbent surfaces best applied by medium Nap roller

- Spray apply over very absorbent surfaces (AAC panel)

- Must be over coated in all systems

Product Performance and Application

Unitex® Cembond Substrate Sealer is for exterior and interior use and offers resistance to early hydrolysis and rain penetration into the substrate. Unitex® Cembond Substrate Sealer can absorb up to 5mm into very porous surfaces.

Unitex® Cembond Substrate Sealer is compatible with all Unitex® acrylic renders and surface applied coatings.

When applying Unitex® Cembond Substrate Sealer please consider the following:

- Apply between 100C and 350C ambient temperature

- Allow 2 hour drying time before top coating in Summer, and 4 hours in Winter

- Generally 1 coat is required (or more if substrate is not fully sealed)

- Roller and spray applied

- Use water if thinning product is required, and in cleaning tools

Slows the drying of the subsequent coat and to be a consideration when rain and cooler conditions is a possibility

| Product size: | 15L pail |

| Coverage: | 50-70m2 (depending on substrate absorbency) 30-40m2 for AAC substrates |

| Substrate suitability: | All absorbent masonry surfaces |

| Application tools: | Roller and Spray |

| Dry time: | Minimum 72 hours at standard conditions (25 degrees celcius and 50% humidty), after application |

| Safe Use: | Refer to the MSDS |

[/av_icon_box][/av_section]