Unitex Trowel-Applied Dry Textures

Unitex Trowel-Applied Dry Textures are dry, powder-based products. They are a cement modified, polymer-based blend of fine marble, quality-graded mineral and polymeric additives to provide a 100% active product. On-site, all that has to be added is water to provide a ready-to-apply finish.

Unitex Applied Texture Finishes are polymer/mineral bound textured coatings designed for decorating interior and exterior walls. Unitex Trowel-Applied Dry Texture Finishes are suitable for use over surfaces prepared with render from the Unitex Specialty Renders range. A one coat application offers a long-life, heavy-duty coating that combines durability and style.

Unitex Applied Texture Finishes are ideal for commercial and residential exterior walls. Due to the strong binding power of the acrylic, an impact resistant coating results. The surface prevents scuffing and is able to withstand hard knocks.

Unitex Uni-Dry Cote® Powder Finishes are supplied in 20kg multi-walled paper sacks. They contain quality graded fine mineral components and aggregates, together with non-absorbent extenders bound by a well-proven polymer system. Typical coverage is 8-12m² per bag.

Finish: Fine Grain

Thickness: Medium (1-2mm)

Product Size: 20kg

Coverage: 8-12m²

Suitable over: Unitex Specialty Renders

Application Tools: Trowel

Dry Time: Minimum 72 Hours at standard conditions

Top Coat: Unitex PTC (1 Coat)

Safe Use: Refer to SDS

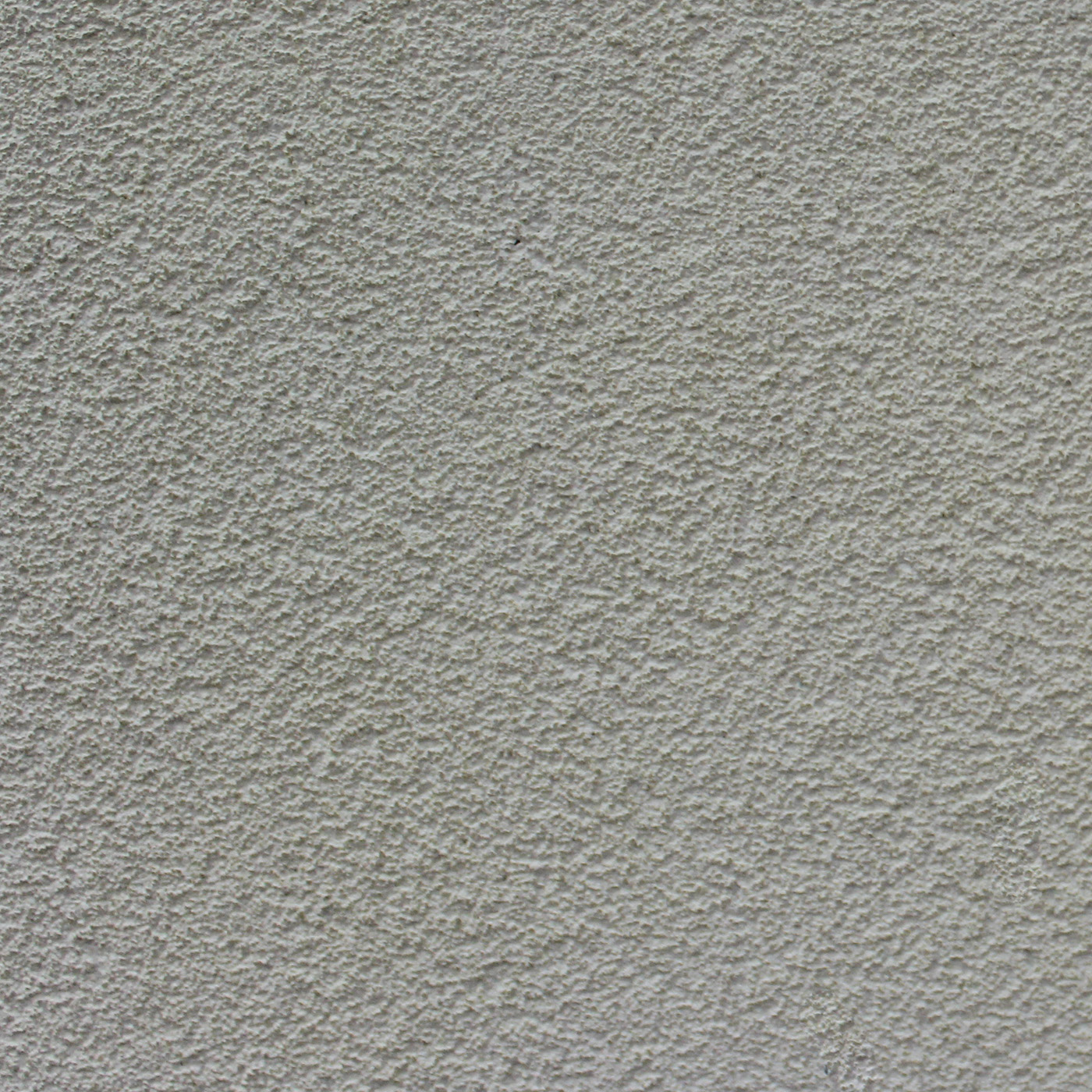

Download SDS Download TDSFinish: Medium Grain

Thickness: Medium (1-2mm)

Product Size: 20kg

Coverage: 8-12m²

Suitable over: Unitex Specialty Renders

Application Tools: Trowel

Dry Time: Minimum 72 Hours at standard conditions

Top Coat: Unitex PTC (1 Coat)

Safe Use: Refer to SDS

Download SDS Download TDSUni-Cote Dry Powder Finishes:

Biological Resistance

Resistance to attack from bacteria and fungi is provided. This product being a cement modified water based polymer system offers safe handling and low toxicity properties. Dirt, grime and dust on the surface of coatings will act as seed beds for bacterial attack, therefore cleaning and maintenance of your coating is essential to hinder bacterial and fungal attack.

Fire Resistance

The full Unitex coating system when subjected to the Early Fire Hazard Tests – Australian Standard AS1530.3:1999 meets the strictest standards.

Water Resistance

The coating, even at exceptionally high build, is formulated with a water vapour permeability factor to rainproof the exterior and allow water vapour from the substrate to leave unhindered. Rising damp and elevated levels of moisture in the substrate will damage, and possibly delaminate, the surface coating. Please ensure that damp coursing the substrate is in place and prior test moisture content with a moisture meter (maximum 12% WME is allowed) (Builder responsibility).

Colour

The Unitex Uni-Dry Cote® Powder Finishes are not pigmented products. They dry on the surface to a ‘cement-off-white’ colour. The desired topcoat colour is achieved by application of a pigmented protective membrane such as Unitex Uni-PTC for a matt surface effect or Unitex Uni-Flex Membrane for a satin surface finish.

Application Details

A minimum of 72 hours, under ideal temperate conditions, is required for through-dry (and cure) of the render, when the surface is through dry the Unitex Textured Finish coat may be applied. Dry is measured to be less than 12% WME (Wood Moisture Equivalent) where measured on a Protimeter® Moisture Meter.

The substrate must be clean before applying the Finish coat. Any crumbling, loose or damaged substrate render must be removed and the surface patched and made good prior to coating. All surfaces must be free of grease, oils, dirt and dust. Pre-painted surfaces must have flaking paint wire brushed back to a sound substrate. Unitex recommends a base coat of a pigmented Unitex Uni-Substrate Sealer (2 coats) over renders prior to application of the surface finishes.

If multi coats are desired then a minimum of 72 hours between each coat is required.

All Unitex Applied Texture Finishes are designed to overcoat Unitex Render from our specialty render range. See Unitex Renders sections for information on suitable base render to use. Unitex Uni-Dry Cote® Powders, when through dry and cured, are to be over coated with two coats of a Unitex Uni-PTC Protective Membrane.

Application should not be carried out under excessively cold conditions (below 7 °C) or in hot windy conditions (above 32°C).

Guide to Good Mixing Consistency

- Add the contents of the bag slowly to 4 litres of water (25% volume of entire bag) with vigorous drill mixing to ensure a lump free render of required slump. Allow to stand for 5-10 minutes and re-whip with mixer to allow efficient wetting and ideal application consistency.

- The mix can be later water thinned to required viscosity within 1 hour of initial mixing.

- Ensure wall surface is stable, clean, dry and free of dust, etc prior to application.

Site

Unitex strongly advises sign off on all coating systems. Always provide the Builder and Designer with a site texture sample of minimum 2m², finish and colour for written approval nominated the Unitex specified system.